Performance Characteristics And Working Range:

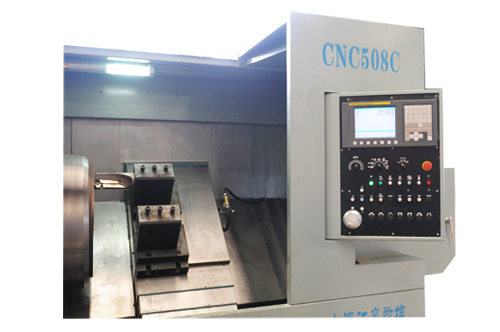

The machine tool is equipped with a FANUC System. Its bed ways of rolling straight guide rails may withstand heavy cutting. With its lathe bed construction with an inclination of 45°, forward-type compressed air chucks, combined CNC power-driven tool head and stationary tool head, the machine tool is characterized by free motions, perfect water resistance and high resetting accuracy.

Specs of parts to be machined: 13-3/8"~ 20", i.e. Φ339.7~Φ508;

Grades of steel of parts to be machined: J55 , N80, P110;

Voluntary standards: API SPEC 5CT (Specifications for Casing and Tubing),API SPEC STD 5B (Specification for Threading, Gauging, and Thread Inspection of Casing, Tubing, and Line Pipe Threads);

Main Specifications Of The Machine Tool:

| Max. swing over bed |

∮1100 |

| Longitudinal travel of tool head (to the end surface of chuck jaw) |

600mm |

| Transverse travel of tool head |

500mm |

| Range of spindle speed |

60-250rpm (variable-frequency and adjustable) |

| Amount of feed and thread-cutting range |

0.25-40mm |

| Spindle bore diameter |

∮550mm |

| No. of tool disk stations |

8+1 |

| Sectional dimension of toolbar |

40 |

| Maximum static torque of longitudinal servomotor |

30n.m |

| Maximum static torque of transverse servomotor |

30n.m |

| Main power |

90kw,960rpm |

| Weight |

27000kg |