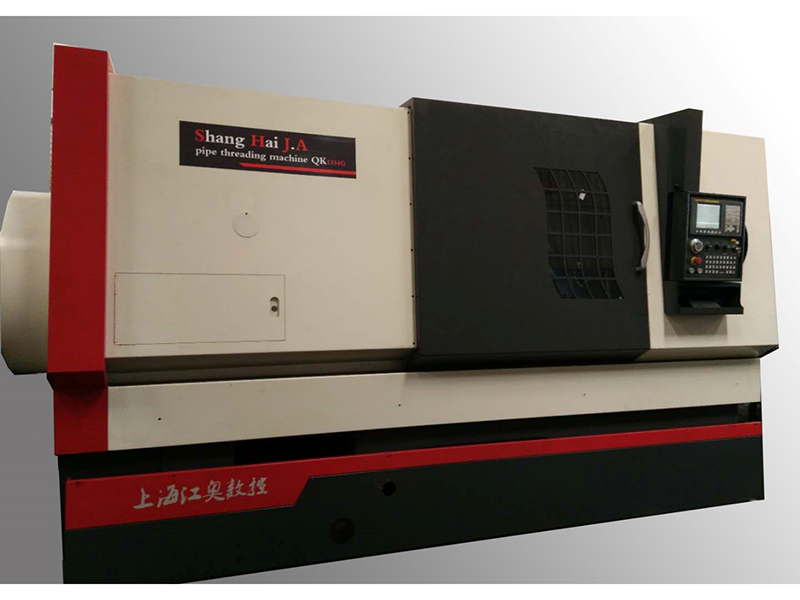

Overview

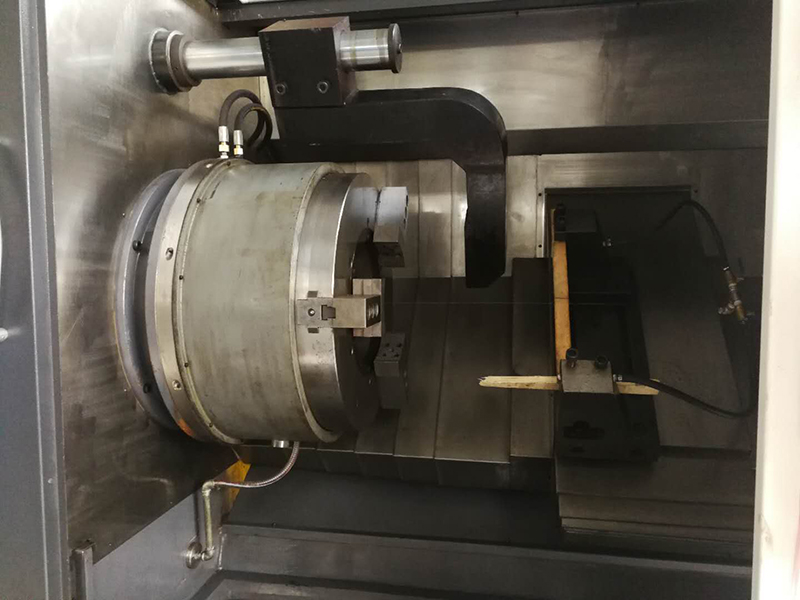

QK1334G CNC pipe thread lathe has a tilting structure. The front and back ends of the machine tool spindle are made of domestic pneumatic or hydraulic chucks. The spindle bearings are ZWZ, HRB, NSK and other domestic famous brands and imported brands. The tool holder is a fixed two-station row. The tool holder and the spindle motor adopt explosion-proof asynchronous motor or main servo motor. The numerical control system is FANUC numerical control system. The front end is equipped with pneumatic fixed-size blocking device and optional automatic chip removal machine.

This machine tool is a large-scale special numerical control equipment used for petroleum casing thread and special thread processing for petroleum casing. It can also be used as a general CNC lathe. Surface, spherical surface, curved surface, and cuts. Large application range, high efficiency, good accuracy and stability, good part size uniformity, easy to operate.

Technical specifications

| project |

unit |

parameter |

Note |

| Processing range |

Swing diameter on bed |

mm |

1000 |

|

| Maximum swing diameter on the saddle |

mm |

550 |

|

| Processing length |

mm |

350 |

|

| Spindle through hole diameter |

mm |

355 |

|

| Tube diameter |

mm |

139.7 ~ 339.72 |

5-1 / 2 "~ 13-3 / 8" |

| Spindle |

Chuck diameter |

mm |

740 |

Pneumatic chuck or hydraulic chuck |

| Spindle center height |

mm |

1270 |

|

| Spindle speed |

r / min |

100 ~ 300 |

Second gear, adjustable frequency |

| main motor power |

kW |

45/55 |

|

| Bed saddle |

slope |

DEG |

45 ° |

|

| Travel distance X / Z |

mm |

380/600 |

|

| Fast moving speed X / Z |

m / min |

8/10 |

|

| Servo motor torque X / Z |

Nm |

22/22 |

|

| Knife holder |

Tool number |

|

2 |

|

| Tool size |

mm |

32 × 32 |

|

| other |

power supply |

kVA |

80 |

380V |

| Gas source |

L / min |

165 |

Air pressure 0.4 ~ 1.0MPa |

| Dimensions (length × width × height) |

mm |

4750 × 2380 × 2320 |

Without box |

| total weight |

kg |

16000 |

|

| machining |

7 "sleeve |

sec / Piece |

120 |

|

| Beat |

9-5 / 8 "sleeve |

sec / Piece |

160 |

|

| 13-3 / 8 "sleeve |

sec / Piece |

200 |

|

| Machine accuracy |

Precision |

|

≥IT6 |

|

| Roundness of machining workpiece |

mm |

≤0.008 |

|

| Cylindricity of workpiece |

mm |

≤0.020 / 300 |

|

| Flatness of machined workpiece |

mm |

≤0.020 / Ф300 |

|

| Surface roughness of machined workpiece |

|

Outer circle Ra1.6μm, arc surface, conical surface Ra3.2μm |

|

| Position accuracy and positioning accuracy X / Z |

mm |

0.015 / 0.02 |

|

| Repeat positioning accuracy X / Z |

mm |

0.008 / 0.012 |

|