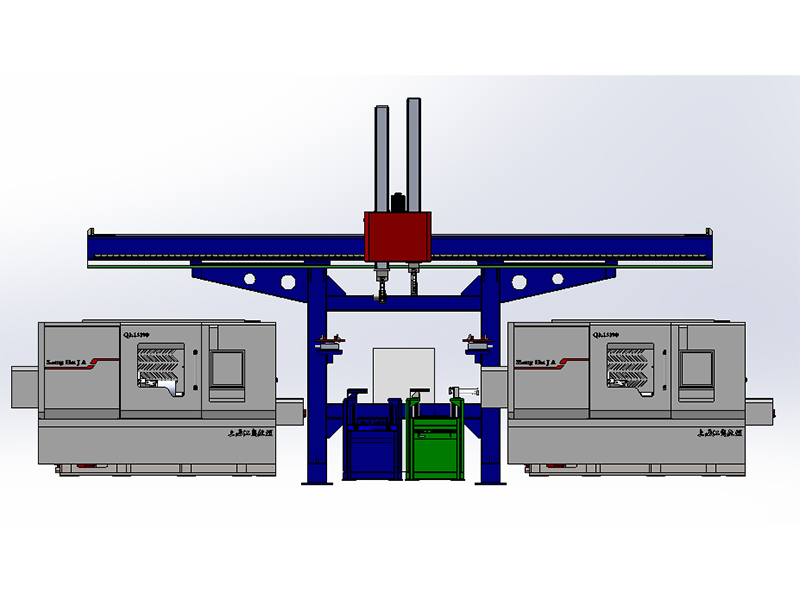

Overview

The CNC140C-2 double spindle and double carriage CNC thread turning machine has a double spindle and double carriage structure, which can simultaneously turn two couplings. The size of the processing coupling is 2-3 / 8 "~ 5-1 / 2 ", the bed is inclined structure, the machine tool spindle chuck uses hydraulic power chuck, the spindle bearings are ZWZ, HRB, NSK and other well-known domestic brands and imported brands, the tool holder at each spindle is a two-station fixed row knife Frame, the spindle motor adopts explosion-proof asynchronous motor or main servo motor, the numerical control system is FANUC numerical control system, and automatic chip removal machine can be optional.

This machine tool is a special numerical control equipment for processing the special threads of petroleum oil casing coupling threads and special threads of petroleum oil casing couplings. It can also be used as a general numerical control machine tool. Cone, sphere, curved surface and cuts. Large application range, high efficiency, good accuracy and stability, good part size uniformity, easy to operate.

Technical specifications

| project |

unit |

parameter |

Note |

| Processing range |

Swing diameter on bed |

mm |

600 |

|

| Maximum swing diameter on the saddle |

mm |

340 |

|

| Processing length |

mm |

340 |

|

| Coupling diameter |

mm |

73 ~ 153.67 |

2-3 / 8 "~ 5-1 / 2" |

| Spindle |

Chuck diameter |

mm |

315/400 |

|

| Spindle center height |

mm |

1040 |

|

| Spindle speed |

r / min |

200 ~ 1000 |

Variable frequency adjustable |

| main motor power |

kW |

15/22 |

2 |

| Bed saddle |

slope |

DEG |

60 ° |

|

| Travel distance X / Z |

mm |

300/500 |

|

| Fast moving speed X / Z |

m / min |

8/10 |

|

| Servo motor torque X / Z |

Nm |

12/12 |

|

| Knife holder |

Tool number |

|

Each 2 |

Electric, hydraulic multi-station automatic tool post can be installed according to demand |

| Tool size |

mm |

φ80 |

|

| other |

power supply |

kVA |

80 |

380V |

| Dimensions (length × width × height) |

mm |

5770 × 1550 × 1990 |

Without box |

| total weight |

kg |

13000 |

|

| Processing cycle |

2-7 / 8 "coupling |

sec / Piece |

45 |

|

| 3-1 / 2 "coupling |

sec / Piece |

45 |

|

| 5-1 / 2 "coupling |

sec / Piece |

80 |

|

| Machine accuracy |

Precision |

|

≥IT6 |

|

| Roundness of machining workpiece |

mm |

≤0.008 |

|

| Cylindricity of workpiece |

mm |

≤0.020 / 300 |

|

| Flatness of machined workpiece |

mm |

≤ 0.030 / Ф300 |

|

| Surface roughness of machined workpiece |

|

Outer circle Ra1.6μm, arc surface, conical surface Ra3.2μm |

|

| Position accuracy and positioning accuracy X / Z |

mm |

0.015 / 0.02 |

|

| Repeat positioning accuracy X / Z |

mm |

0.008 / 0.012 |

|

Products